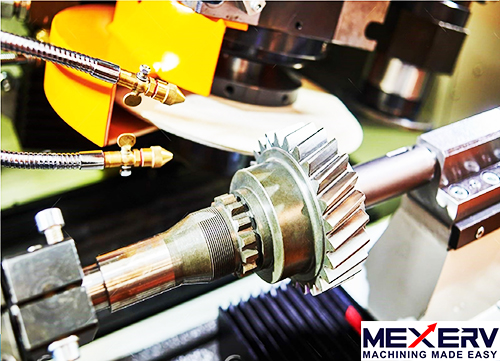

Helical Gear Hobbing

Helical gears are often used as power transmitting gears because they can carry larger loads and additionally their noise and vibration levels during operation are much lower compared to spur gears.Helical gears functional similarly to spur gears except that their teeth are cut at an angle to the hole or axis as opposed to straight and parallel to the hole like spur gears. The line of contact between two teeth in helical gears is inclined. This makes sure that there is gradual engagement of teeth from one end of the tooth to the other rather than a sudden engagement as in the case of spur gears. This gradual engagement is also the reason for the smooth functioning of the gears with as much less noise as possible.

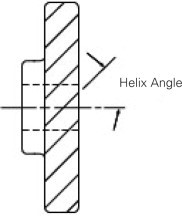

Helix angle – The helix angle is the angle between the axis of a helical gear and an imaginary line tangent to the tooth. The helix angle shall be between 0 ° and 90 °. This is an important parameter in the design and manufacture of helical gears.